THE DOOR TO THE FUTURE HYDROGEN-HOW, WHEN AND WHERE

THE DOOR TO THE FUTURE

HYDROGEN-HOW, WHEN AND WHERE

Hydrogen is the energy pillar of the Universe, but we are taking very marginal advantage of its full potential, both nuclear and chemical. Though progresses are being made, controlled nuclear fusion is years away, but no doubt research must invest all the available capitals because there is the key to ultimate energy reserves. We are exploiting its chemical energy by burning hydrogen in rocket motors with very positive results since hydrogen generates the highest specific impulse of any rocket fuel, thus the highest thrust and highest exhaust gases ejection speed, which in outer space translates into superior performances in terms of acceleration and ultimate speed.

Now the aerospace industry is evaluating the possibility of developing passenger aircrafts that will burn hydrogen in their turbofans to reduce emissions of CO2 and of the other pollutants related to the use of present jet fuels. The transition will not be easy. The cryogenic problems connected to the storage and handling of liquefied hydrogen (20.15 K) are known, yet tanks of consistent insulating capability have been developed, tested and installed on both space vehicles and experimental cars.

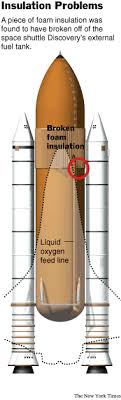

The Space Shuttle external tank is a great example of highly refined technology being an enormous football shaped container almost 47 meters long and almost 8.5 meters in diameter that containes 1,476,837 liters of liquefied H2 and 549,407 liters of liquefied O2 (temp. 90.37 K). The final and lighter version of the external tank was made from an aluminum-lithium alloy. Earlier versions were made of multiple layers of aluminum, steel alloy and titanium.

The insulating capability was obtained by spraying a foam of high insulating capability on the outside of the tank. Efficient and rational. Liquefied hydrogen tanks on experimental cars were built in steel alloy and duly wrapped in a layer of insulating material.

Again, the cryogenic problems appeared relatively easy to address by our present technology. The real problem with hydrogen, even in liquefied state, is its low density. For a comparison, the much larger volume of hydrogen in the Shuttle tank only weighed 104,308 kilograms, the much lesser quantity of oxygen weighed 625,850 kilograms. This leads to conclude that a B747-8 class passenger aircraft would need a tank as large as its whole fuselage to duplicate the range capability of the present jet-A fueled version. Under the pressure of “green” European Parliament and Commission, Airbus seems determined to build a hydrogen fueled transport aircraft, and they might have an assisted start to that. It would only take them to restart production of defunct mega-jumbo A380 and use the upper deck to store the amount of liquid hydrogen it would take to fly across the Atlantic.

At this stage, using hydrogen to fuel large transport aircrafts borders on total impracticality and would kill all possibility of further evolution of the renewed interest of the industry toward the realization of supersonic passenger aircrafts. NASA X59 QueSST experimental aircraft due to probe the possibility of developing low sonic boom passenger aircrafts appears beautifully slim, sharp, like not even Concorde ever was. Some projects following the NASA concept, like Aerion AS2, refer to a 12 passengers, 1.5 Mach capable business jet that could never achieve the expected performance in case it should be dimensioned to be fueled on hydrogen.

It is my humble opinion that all this enthusiasm about switching the next generation aircrafts to hydrogen fueling must be duly verified in terms of rationality and global efficiency. In all this drive to greener technologies I see massive scientific and technical incompetence from our Greta influenced politicians. Present turbojets, turbofans, turboprops or even ramjets would have no problem switching to hydrogen, they would only require fuel delivery and metering modification to correctly burn hydrogen with great efficiency. The problem is not there, but in storing hydrogen in volumes adequate to the needs of a transatlantic flight. Even if air breathing jet engines would burn hydrogen at a much lesser rate than rocket engines, the size of the tanks remains a huge problem. Greta and her follower never even took liquid hydrogen low density into consideration. Well, Greta did not take into consideration anything of scientific value.

Liquefied methane (natural gas) might represent a positive alternative. First for its energy density, almost three times that of liquefied hydrogen: 22.5 MJ/liter vs. 8,49 MJ/liter. Its specific impulse is lower, but its density is much higher, about seven times that of hydrogen: 500 grams/liter vs. 71 grams/liter. At 111.1 K, liquefied natural gas poses less cryogenic problems and, most meaningful, the industry already developed and collected very large and positive experience in handling and safely storing it since natural gas travels liquefied in huge LNG carrier ships.

The combustion of CH4 still generates CO2, but no particulate or any other solid pollutants and that alone would be a huge step forward in terms of environmental compatibility, without penalizing our ability to travel fast. And not only thru the skies. LNG would be the perfect fuel to keep our beloved spark ignited piston engines alive for a good number of years. At 130 RON, LNG boasts the highest “natural” octane number of all hydro-carbon fuels and, as I said it only generates CO2 and, of course, NOx and no particulate, while allowing near-diesel engines compression ratios, which means thermodynamic efficiency never heard of in the field. We own the technology to create direct injection LNG fueled engine from the days injection specialists Stanadyne created pencil type injectors for the direct liquid hydrogen injection system that fed the BMW 3.6 liter six cylinder experimental unit.

That was a terrific technological achievement for the Windsor, CT, Company and one that opens the road to the development of ultrahigh efficiency ignition sparked engines that would almost match the efficiency of Diesel cycle engines, but with very limited “side effects”. Prior to scrapping millions of dollars of castings, molds, tooling and an enormous wealth of experience and knowledge in piston engines refinement and waste more money in the further development of ridiculously low energetic efficiency lithium-ions batteries it might be worth looking into the opportunities and potential that LNG offers to the automotive industry for a well calibrated, smooth evolution toward a more rational and cleaner use of our energy reserves. BMW’s years long attempts to realize credible hydrogen fueled spark ignition engines finally confirmed that hydrogen is the perfect fuel for all kinds of engines, but piston engines. Its octane rating is equivalent to 80 RON, a pre WW I gasoline at its best, and that killed the performance potential of all the spark ignition engines that BMW attempted to convert to hydrogen fueling. The mighty 5.4 liter V12 that at the time delivered an easy 355Hp on gasoline, when adapted to inhale hydrogen was hardly making 210Hp.

Low octane numbers hydrocarbon fuels usually turn into high cetane numbers fuels, since a linear blending relationship was found to exist between the cetane and octane numbers. I have no idea if this was ever investigated about hydrogen. Given its very low temperature, liquid hydrogen might pose problem to the self-ignition process Diesel cycle engines are based on. Yet hydrogen might offer positive opportunities to the “green” evolution of Diesel cycle engines acting as secondary fuel injected in the combustion chamber after a small charge of regular diesel fuel ignites. In this case the low temperature of liquid hydrogen would not pose any ignition problem and the amount of the hydrogen charge might be progressively increased.

Diesel cycle units are the most thermodynamically efficient engines of all, and, according to leading specialists Bosch, the latest development of their injection and management systems reduced ten times the emission of NOx and other secondary pollutants, particulate included. The war against Diesel cycle engines started by “green” groups and politicians is simply ignoring the very brilliant results of the efforts the Industry spent to evolve its environmental compatibility. An ideological war that is scientifically inconsistent and solely politically supported. I personally believe that it might be worth investigating the potential of hydrogen burning Diesel cycle engines. The ultimate use of hydrogen in land and air propulsion is associated to the development of further evolved fuel cells. Fuel cells are the only realistic answer to the demand of efficient electric propulsion systems.

Lithium-ions batteries are a sour joke if we just evaluate their energy density. It takes almost 900 kilos of batteries to obtain an energy reserve of 90-94 Kw/h to ensure a 400/450km range at an average cruising speed. I leave aside any obvious consideration about the recharging time because the problem is well known, but I would strongly underline that disposing of spent batteries will create an environmental problem of enormous proportions. And in the process we will funnel millions of our Dollars or Euros to China, and that is another sour joke since China is no friend to anyone. Add to all that that fire safety is still an issue with lithium ions batteries. General Motors just recalled 69,000 units of Chevy Bolt EV on battery spontaneous ignition problems and issued instructions to the owners not to exceed 90 per cent charge. Lithium ions batteries already caused many accidents of that kind, some with tragic consequences.

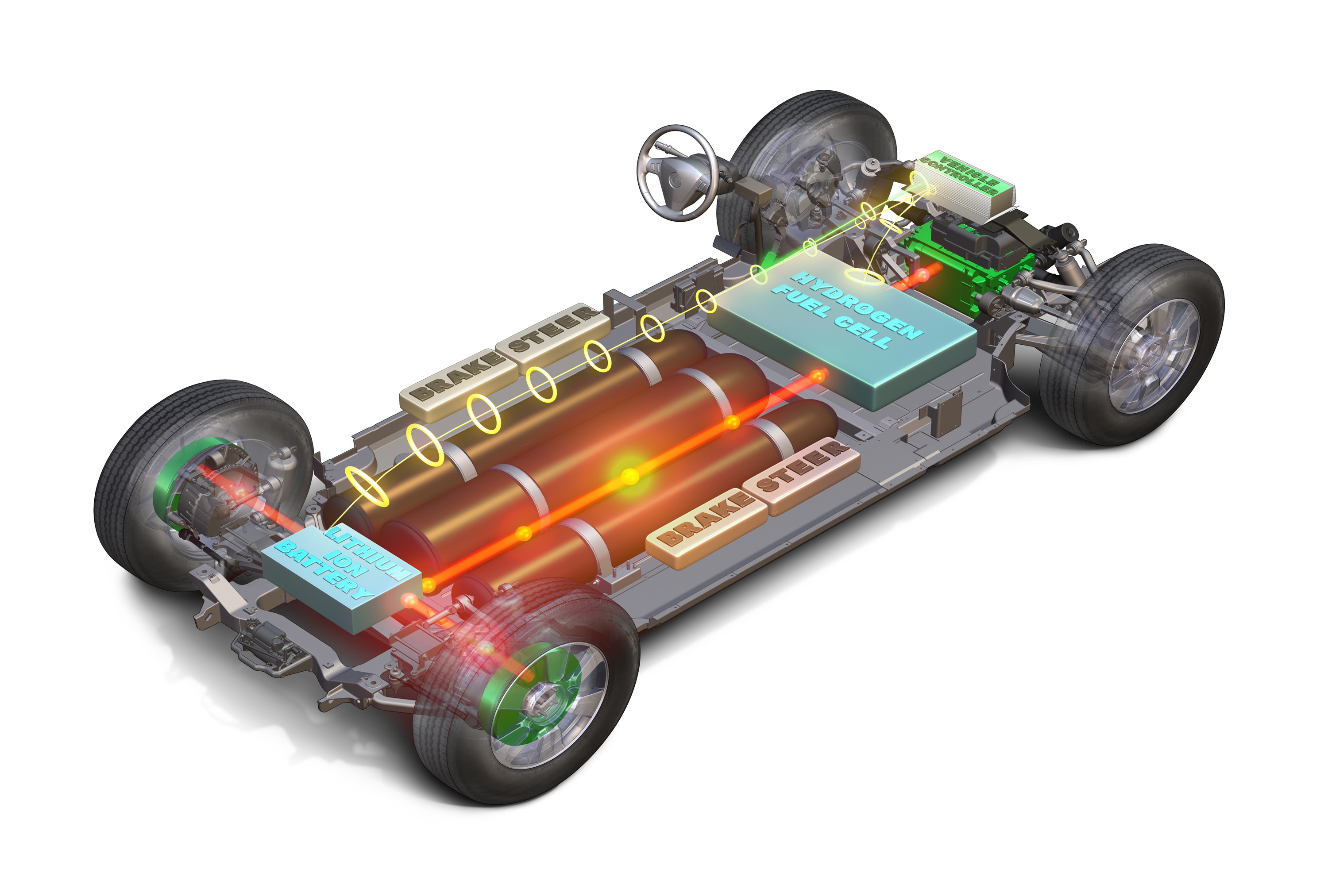

Tightly packed cells to reduce battery volume are at the base of the problem and the issue will keep going around in circle as a consequence of the constant attempt to increase the practical range of battery powered cars. Energy density is no problem with fuel cells and refueling time is same as with any internal combustion engine car. Years ago Mercedes set up a multiple test to show how advanced they were in the various aspects of electric propulsion technology. For the purpose they lined up a number of A class compact sedans filled with lithium ions batteries up to their ears plus one energized by an experimental fuel cell. I had the opportunity to test both the battery and the fuel cell versions and there was no comparison.

Given the same electric motor, the energy density of the throttle response of the fuel cell powered car was very markedly superior to that of the battery powered one. Fuel cells have gone a long way since 1801, when our old ones identified the principles of the electro-chemical process on which the fuel cell works. It took till, around 1950, when General Electric created the first proton exchange electrolyte membrane. From then on fuel cells became operational and were used by NASA to power their satellites.

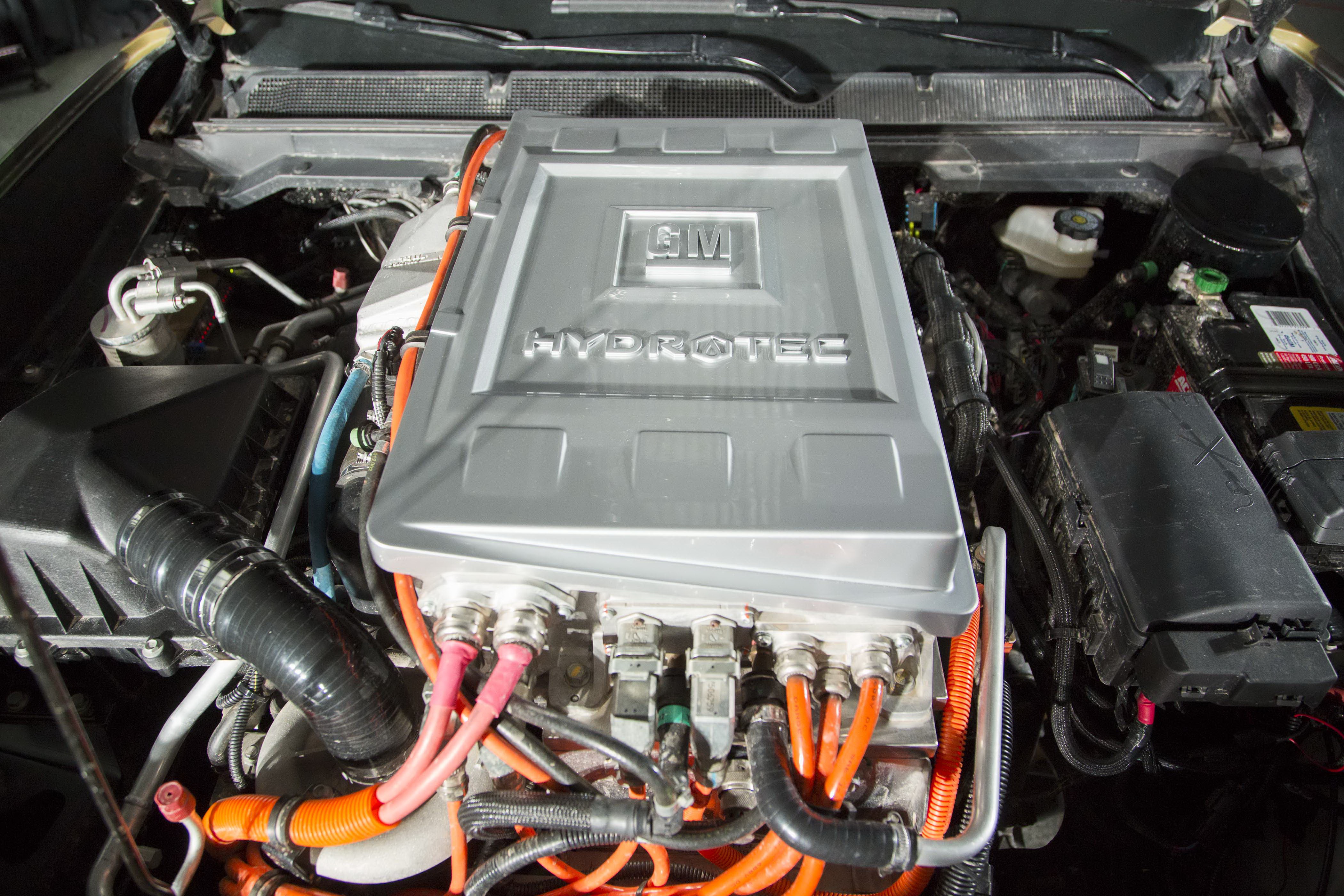

The automotive industry never stopped working to the refinement and optimization of automotive fuel cells in terms of specific output in relation to size and to weight. Honda and Hyundai developed an put in limited production very efficient fuel cell powered models, General Motors, that was way ahead of all competition back in the 1990 years with the Sequel project, now is back on fuel cells development and recently delivered to the US Army a fuel cell powered Silverado pick-up. And there is a whole generation of large buses and trains that feed their electric motors with the electricity from fuel cells. Cummings, yes Cumming the legendary US turbodiesel specialists, were granted 4.6 million dollars by President Trump for the development of a new generation of solid state fuel cells that might represent a huge step forward in the global functionality and efficiency of fuel cells for a number of applications, automotive propulsion included. Fuel cells can be fed by a number of fossil or organic fuels, like natural gas and methanol. The final result is an energy conversion more efficient that any combustion process.

Problem is that natural gas, methanol, butane or any other carbon based fuel will inevitably produce CO2. I mention this not because I myself am a member of the fanatic anti CO2 congregation led by ridiculously ignorant Greta Thunberg, but because the CO2 always surfaces whenever we talk of propulsion, and I want to buffer that. Fuel cells offer the ultimate solution to our environmental problem in that they convert hydrogen into electric energy with supreme efficiency. Problem is that around the world there are very few taps that we can draw hydrogen from and hydrogen does not come cheap. I have been horrified hearing supposedly very competent colleagues and researchers theorizing the extraction of hydrogen from natural gas.

Leave natural gas alone, it is a perfect fuel as it is. Hydrogen must come from water in order to start a virtuous cycle, since hydrogen oxidized in the fuel cell returns to water, in a perpetual cycle. To separate hydrogen from oxygen in the very stable water molecula it takes a lot of energy and the process ends in a 5 per cent energy loss. But we have a trump card up our sleeve: electronuclear powerplants. I know that by mentioning the term nuclear I scare a lot of souls who immediately think of Chernobyl, but that is not the case with properly designed, managed and kept third and fourth generation nuclear reactors. There steam going to the turbines of the generators reaches temperatures in the region of 1100 K. And is not radioactive. Instead of simply cooling it in the cooling towers we must drive it to a catalytic chamber where a chemical catalyzer is added.

The combined action of the very high temperature and of the catalyzer separates hydrogen from oxygen with no need of any additional treatment and at the end hydrogen, oxygen and the catalyzer are recovered. This way hydrogen is the byproduct of the generation of electric energy and it would come at ultralow cost and in great quantities. This process is known from the 1970s years and there are 4-5 variations of the same basic concept, according to the nuclear research centers and laboratories that developed and tested them.

And they all work perfectly. But no major industry ever showed interest, till it gloriously surfaced at a very strong alternative propulsion systems seminar held by General Motors at Belle Isle, in the Detroit River (MI). There was a lot of hand shakings at the end. Today GM CEO Mary Barra seems to be sold on batteries, I hope she will soon switch to hydrogen fueled fuel cells. At Warren (MI) R&D Center they know how to do it big time. Remember the GM Sequel prototypes.